CENTRIFUGAL CASTINGS

With a team of skilled professionals, we ensure the highest quality standards in every centrifugal casting project we undertake. From custom molded designs to mass production and its inspection, we are equipped to handle projects of all sizes with precision and expertise.

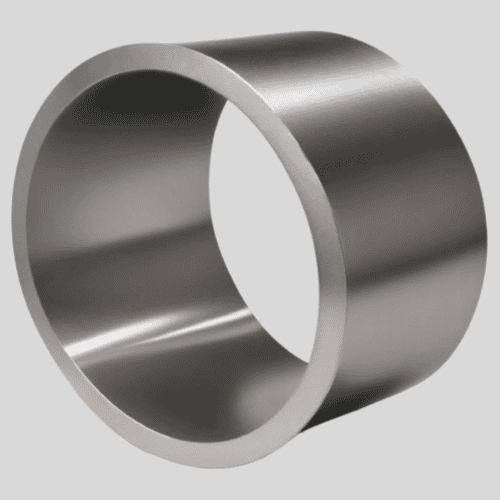

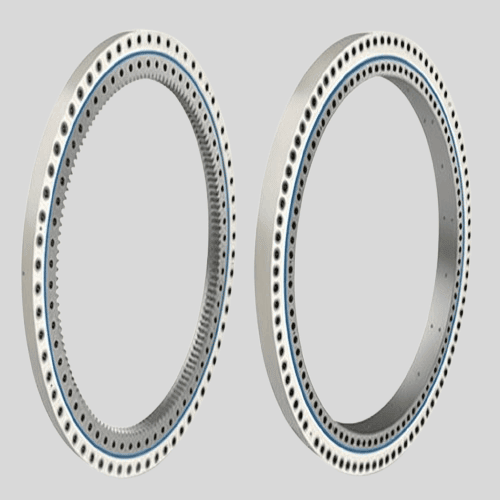

The molten metal is thrown against the mould wall and help spread the molten material evenly. The cast parts solidify with more finely compacted metal grains than other processes, they tend to provide stronger, more corrosion-resistant components. These items display excellent mechanical properties. Centrifugal casting is typically employed for parts with rotational symmetry, such as discs, rings, cylinders, pipes, pulleys, wheels and rings.

Vertical centrifugal casting process is employed for cylindrical shapes where the diameter exceeds the height or length of the cylinder to produce components. Horizontal casting process is for manufacturing products with long cylindrical parts, where the length of the casting significantly exceeds the outside diameter.

True Centrifugal Casting

This does not require the use of an interior mold core. The spinning of the symmetrical mold around its central axis causes the metal to disperse through the mold and create a cylindrical casting with a hollowed rounded interior. Metal parts utilizing true centrifugal casting are engine cylinders, ring pistons, and pipes.

Semi Centrifugal Casting

This Process has addition of a central core to the mold determines the shape of the interior hole in the casting. The production process still relies upon rotating molds to obtain finely grained castings. Products manufactured using semi centrifugal casting include flanges, sprockets, valves, propellers track wheels, railroad car wheels and fly wheels.

Centrifuge Casting

It involves spinning several small molds around a central axis, much as test tubes rotate positioned within a centrifuge. The individual molds grouped in this manner may include asymmetrical molds. Molten metal enters the mold via a central sprue and disperses through the interior along a network of precut channels for casting such as gears, disc-shaped metal components and several small parts with fine grains.

MATERIAL GRADES & APPLICATIONS:

| MATERIAL TYPE | ASTM GRADE | PRODUCTS | USABILITY |

|---|---|---|---|

| Iron Alloys | ASTM A48 (Grey Cast Iron) | Engine Blocks, Pipes, Pump Housings | Excellent machinability and vibration damping, used for automotive and infrastructure segments. |

| ASTM A536 (Ductile Iron) | Gears, Crankshafts, Pressure Pipes | High strength and ductility make it ideal for load-bearing and pressure-bearing applications. | |

| ASTM A897 (ADI - Austempered Ductile Iron) | Suspension Components, Gearboxes | Superior toughness and wear resistance, used in heavy-duty and high-wear conditions. | |

| Steel Alloys | ASTM A216 (Carbon Steel) | Valves, Flanges, Pressure Vessels | Offers high strength and heat resistance, suitable for high-pressure environments. |

| ASTM A27 (Low-Carbon Steel) | Structural Parts and Machine Components | Provides good toughness and weldability, used in structural and machinery parts. | |

| Stainless Steel and Nickel Alloys | ASTM A351 (CF3, CF8, CF8M, CF3M) | Pumps, Valves, Chemical Processing Parts | Excellent corrosion resistance, used in chemical, marine, and high-temperature environments. |

| ASTM A494 (Nickel Alloys: CY40, CW6M) | Turbine Components, Chemical Reactors | High-temperature and corrosion resistance, used in demanding environments such as aerospace and chemical plants. | |

| Copper Alloys and Copper Extrusions | ASTM B271 (C90300, C90700) | Bearings, Bushings, Marine Fittings | Superior wear and corrosion resistance, ideal for marine and industrial applications. |

| ASTM B271 (C83600, C84400) | Plumbing Fittings, Ornamental Parts | Good machinability and corrosion resistance, commonly used in plumbing and decorative products. | |

| Aluminum and Alloys Castings | ASTM B26 (356.0, 443.0) | Automotive Parts, Aerospace Structural Components | Lightweight and corrosion-resistant, used for high-strength applications in automotive and aerospace. |

| ASTM B26 (201.0, 221.0) | Aerospace Structural Parts | High strength-to-weight ratio, essential for aerospace components requiring enhanced performance. |

CENTRIFUGAL CASTINGS

Piston Head

Sleeve

Roll Bodies

Precision Bush

Speciality Joints

Turbine Bearing

COMPREHENSIVE SOLUTIONS

3-STAGE QUALITY CONTROL PROCESS & INSPECTION:

- The quality assessment process with special testing equipment ensures only the finest products reach the buyers and customers.

- Here at Calmet, all the employees receive in-depth trainning, guidance, and potential elevation from the mentors or immediate managers who are always observant of the continuous progress and Lean philosophy (Kaizen).

- This intensive process ensures that the employees are well-equipped with the knowledge and work techniques as per their role in the organization.

- This task and its needed output will be perfect if performed with thorough understanding. It's crucial for our quality department to look in and stringently advise on any necessary changes to be made to ensure the scope of errors is minimized or removed.

Raw material

- Immersion Spectrometer with 24 Elements

- Sand Testing Facilities

- Universal Tensile Testing Machine

- Image Analyzer

- On-line Mould checking Facilities

Dimensional

- Coordinate Measuring Machine (CNC-CMM) – Range: 1m x 1m

- Linear Measuring Machine (LMM) – Range: 1m x 1m

- Profile Projector

- Digital Height Gauge – Range: 1m

- All kinds of Inspection Gauges & Instruments

Specialized

- Non-Destructive Test (X-ray)

- Ultrasonic Test

- Dye Penetrant Test

- Hydro Test

- Millipore Cleanliness Test

- Static Balancing

CASE STUDY:

Expertise demonstration

Client Overview

A leading global oil and gas equipment manufacturer required high-precision stainless steel castings for their critical subsea pipeline systems. These components had to meet stringent standards for corrosion resistance, high pressure, and extreme environmental conditions in offshore drilling operations.

Project Scope

- Industry: Oil & Gas

- Material: ASTM A351 CF8M (Stainless Steel)

- Component: Subsea pipeline fittings and connectors

- Quantity: 500 units

- Size Range: 10 inches to 30 inches in diameter

- Lead Time: 12 weeks

The client needed large-diameter stainless steel components that could withstand harsh subsea environments while maintaining structural integrity and precision tolerances. The centrifugal casting process was identified as the best approach to achieve the required properties and dimensional accuracy.

Challenges

-

Complex Geometry: The components had intricate internal passages that required precision casting to avoid machining errors and costly rework.

-

Corrosion Resistance: The parts had to endure prolonged exposure to seawater and high-pressure conditions, necessitating the use of premium-grade stainless steel (ASTM A351 CF8M).

-

Large Size: The castings ranged up to 30 inches in diameter, requiring expertise in handling large molds and ensuring uniformity in such large components.

-

Tight Lead Time: The client requested delivery within 12 weeks to meet their project deadline, necessitating careful planning and efficient production management

Advanced Material Selection

Our engineering team at Calmet recommended using ASTM A351 CF8M stainless steel, known for its excellent corrosion resistance and mechanical strength, which is critical for offshore and subsea applications. This grade was ideal for withstanding both the mechanical stresses and the corrosive environment of saltwater.

Precision Centrifugal Casting

By employing the centrifugal casting process, we at Calmet ensured that the material was free from internal porosity and voids, delivering superior mechanical properties:

-

Centrifugal force during casting resulted in a dense, fine-grained structure, ideal for high-strength applications.

-

The ability to cast thin-walled sections enabled us to meet the complex geometry requirements of the component.

-

Automated control of mold rotation speeds allowed for precise dimensional tolerances, reducing the need for post-casting machining.

Collaborative Design Optimization

We collaborated closely with the client’s design engineers to optimize the mold design and gating system for this large casting. Finite element analysis (FEA) was employed to simulate the casting process and predict any potential issues with solidification and shrinkage.

Efficient Production Management

Given the tight lead time, we implemented a parallel production strategy using multiple casting machines simultaneously. This approach, combined with our in-house heat treatment and non-destructive testing (NDT) facilities, ensured that we maintained quality while adhering to the schedule.

Results

Exceeding Client Expectations

-

Precision Castings Delivered: All 500 units were produced with zero defects, meeting the client’s stringent requirements.

-

Lead Time Achieved: The project was completed two weeks ahead of schedule, allowing the client to meet their project milestones without delay.

-

Improved Component Performance: The superior quality of the castings resulted in components with enhanced durability and longer service life, significantly reducing the client’s maintenance costs over time.

-

Cost Savings: By minimizing the need for post-casting machining and rework, we helped the client save approximately 15% on the total project cost compared to traditional casting methods.

WHY CALMET?

To maintain a competitive advantage in the steel casting industry, Calmet always evaluates its unique strengths and value proposition. Here are some factors to consider while analyzing the competitive advantage that Calmet offers:

Quality and Expertise

• Expertise and experience in specialized processes provide an edge over competitors.

• Certification of quality standards, adherence to industry-specific regulations, and continuous improvement initiatives have immensely helped Calmet and its customers.

Technological Capabilities

- Cutting-edge technology and equipment that Calmet employs significantly enhance the efficiency and quality of the manufacturing process.

- Investment in advanced machinery, automation, and digital tools can lead to cost savings, faster production cycles, and better casting outcomes.

- Strong R&D capabilities to develop new alloys and casting methods can differentiate a firm from its competitors and attract customers seeking innovative solutions.

Supply Chain Management

- Efficient supply chain management, including sourcing raw materials, logistics, and inventory control, can optimize costs and lead times.

- Building reliable relationships with suppliers and ensuring a steady supply of high-quality raw materials can give the firm an advantage in meeting customer demands promptly.

- Implementing just-in-time manufacturing practices and adopting lean principles can enhance competitiveness by minimizing waste and maximizing efficiency.

Customer Relationships

- Developing strong customer relationships and providing exceptional customer service is a way of life at Calmet. Every employee is dedicated to this philosophy.

- Understanding customer requirements, providing technical support, and offering customized solutions have helped us stand ahead of competitors.

- Regular communication and engagement with customers to gather feedback and address concerns helps in continuous improvement and maintaining a competitive edge.

Cost Efficiency

- To remain competitive, controlling costs throughout the manufacturing process is crucial at Calmet.

- Implementing cost-effective production strategies, optimizing resource utilization, and managing overhead expenses helps minimize costs.

- Continuous evaluation of cost drivers and exploring opportunities to enhance operational efficiency contribute to long-term profitability and competitive advantage.

Sustainable Manufacturing

Sustainable manufacturing focuses on minimizing the environmental impact and maximizing resource efficiency throughout the manufacturing process using the below commonly used techniques:

- Energy Efficiency: Implementing energy-efficient measures like optimizing furnace operations, adopting energy-saving technologies, and utilizing renewable energy sources.

- Waste Management: Implementing effective waste management techniques, including recycling and reusing materials, reducing waste generation, and implementing proper disposal methods.

- Resource Conservation: Employing techniques to reduce water consumption, optimize raw material usage, and minimize emissions.

- Supply Chain Transparency: Ensuring transparency and responsibility in the supply chain, such as sourcing materials from sustainable suppliers and monitoring the social and environmental impacts of the supply chain.

New Technologies

Innovative technologies can revolutionize the casting industry, enhancing efficiency, quality, and customization capabilities. Some notable advancements at Calmet include:

- 3D Printing: The introduction of 3D printing in centrifugal casting allows for complex shapes and design optimization, reducing material waste and lead times while enabling customization.

- Automation and Robotics: Integration of automation and robotics streamlines production processes, enhances precision, improves safety, and increases productivity.

- Data Analytics and AI: Leveraging data analytics and artificial intelligence can enhance quality control, predictive maintenance, and process optimization, resulting in improved efficiency, reduced costs, and enhanced product quality.

- Augmented Reality (AR): AR technology can assist in training, remote maintenance and repair, and real-time quality assurance, improving operational efficiency and reducing downtime.

Industry Regulations

The casting industry is subject to various regulations, which ensure safety, quality, and environmental compliance. Key regulations include:

- Workplace Safety: Regulations governing occupational health and safety, including maintaining safe working conditions, providing proper protective equipment, and adhering to workforce safety standards.

- Environmental Compliance: Regulations related to emissions control, waste management, pollution prevention, and resource conservation to mitigate the environmental impact of operations.

- Quality Standards: Compliance with quality certifications such as ISO 9001 ensures that products and processes meet internationally recognized quality standards, fostering customer trust.

- Supply Chain Traceability: Regulations and standards may require documentation and traceability of raw materials, ensuring responsible sourcing and avoiding materials with ethical or environmental concerns.

Keeping abreast of these regulations and proactively implementing compliance measures helps a firm maintain its reputation, enhance customer confidence, and demonstrate commitment to sustainability.