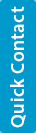

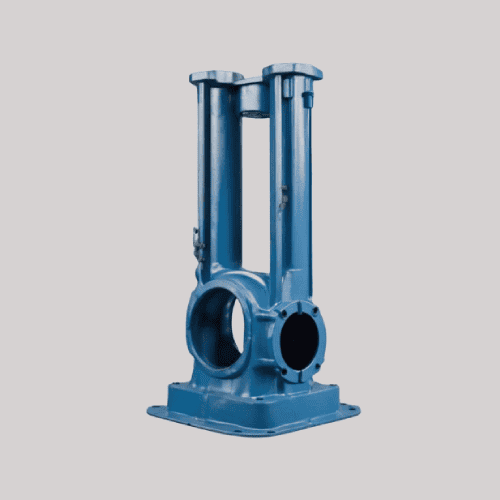

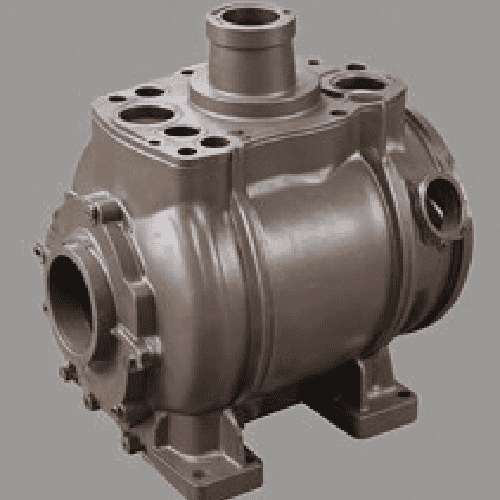

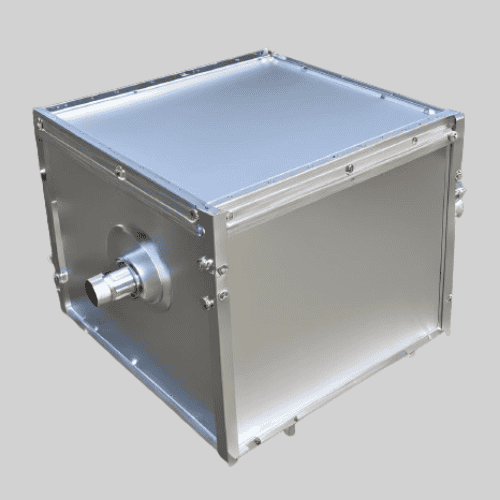

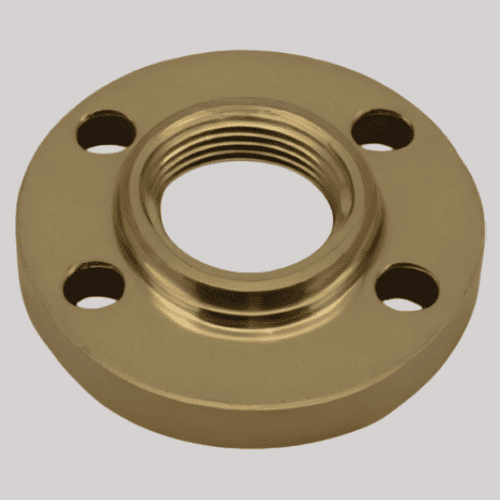

CUSTOM MANUFACTURING

Calmet brings your ideas to life with high-quality casting and forging solutions tailored to your unique requirements. By integrating precision with personalization, Calmet transforms your perspective on production and design.

Even though the initial costs for custom manufacturing processes may be relatively higher, its ability to improve the production process and prevent waste leads to long-term cost savings, with the benefit of scalability taking advantage of rapid manufacturing processes and short lead times to create products when customers demand.

As a trusted partner in the manufacturing industry, we combine cutting-edge technology, skilled craftsmanship, and a commitment to excellence to deliver products that exceed expectations.