Iron Castings

Welcome to our iron-casting manufacturing hub, where precision meets strength. Explore our diverse range of iron casting solutions, meticulously crafted to meet industry standards and your unique specifications. From alloy selection to final inspection, we ensure the highest quality at every step. Trust us to bring your vision to life with durable, reliable, and precisely engineered iron castings. Discover the excellence that defines us – your trusted partner in iron-casting innovation.

Green Sand Casting

Green sand casting is a method that involves using a mixture of sand, clay, and water to create molds. The mold is created by packing the mixture around a pattern, which is then removed to create a cavity for casting. Molten metal is poured into the cavity, and the mold allows for the creation of complex intricate designs. After solidification, the sand mold is broken to retrieve the finished cast part. Green sand casting is cost-effective and versatile, making it suitable for parts in the automotive, machinery, and agriculture industries.

Shell Mold Casting

Chemical sand casting, also known as no-bake molding, is a method using a chemically bonded sand mixture instead of traditional green sand. Chemically Bonded sand molds are created using a wood, metal, or plastic pattern. It involves packing a mixture of sand, resin, and catalyst around a pattern, and hardening it with a catalyst. This allows greater dimensional accuracy, finer surface finish, & reduced casting defects, making it apt for high-precision applications in industries like aerospace and defense.

Air Set (No Bake) Casting

Air-set casting uses chemically bonded sand molds created using a mixture of sand and resin binders. The mold is hardened through exposure to air rather than heat. This method is ideal for intricate and complex parts but requires a longer curing time and additional processing steps. This process is compatible with most pattern materials to produce castings with smoother surfaces than coarse green sand. This method is slightly expensive, but is chosen when deep narrow pockets in the pattern are necessary.

Material Grade & Properties:

| Type of Iron | Carbon | Silicon | Manganese | Sulfur | Phosphorus |

|---|---|---|---|---|---|

| Gray | 2.5 – 4.0 | 1.0 – 3.0 | 0.2 – 1.0 | 0.02 – 0.25 | 0.02 – 1.0 |

| Ductile | 3.0 – 4.0 | 1.8 – 2.8 | 0.1 – 1.0 | 0.01 – 0.03 | 0.01 – 0.1 |

| Compacted Graphite | 2.5 – 4.0 | 1.0 – 3.0 | 0.2 – 1.0 | 0.01 – 0.03 | 0.01 – 0.1 |

| Malleable (Cast White) | 2.0 – 2.9 | 0.9 – 1.9 | 0.15 – 1.2 | 0.02 – 0.2 | 0.02 – 0.2 |

| White | 1.8 – 3.6 | 0.5 – 1.9 | 0.25 – 0.8 | 0.06 – 0.2 | 0.06 – 0.2 |

| Brinell Hardness | Tensile Strength | Modulus of Elasticity | % Elongation (in 50 mm) | |

|---|---|---|---|---|

| Gray iron class 25 | 187 | 29.9 ksi | 16.1 Msi | - |

| Gray iron class 40 | 235 | 41.9 ksi | 18.2 Msi | - |

| Ductile iron grade 60-40-18 | 130 – 170 | 60 ksi | 24.5 Msi | - |

| Ductile iron grade 129-90-02 | 240 – 300 | 120 ksi | 25.5 Msi | - |

| CGI grade 250 | 179 max | 36.2 ksi min | - | 3 |

| CGI grade 450 | 207 – 269 | 65.2 ksi min | - | 1 |

Iron Castings

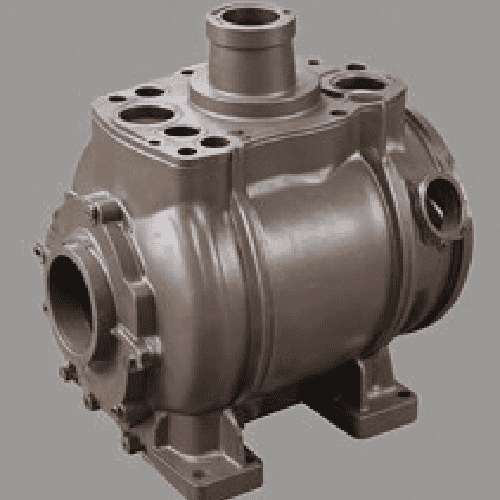

Slurry Dredge Pump

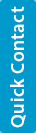

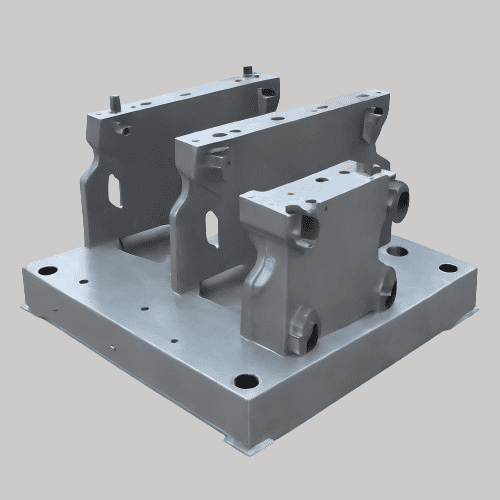

Pump Pedestal

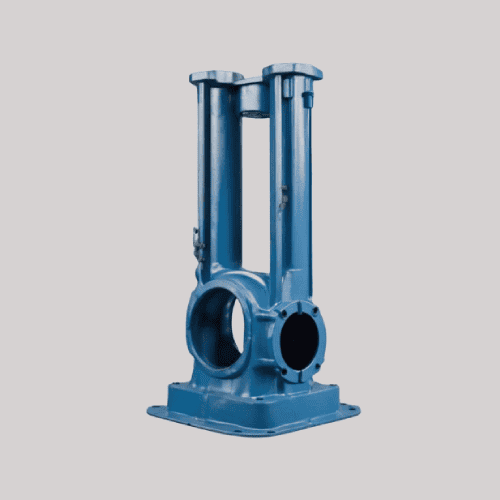

Pump Impeller

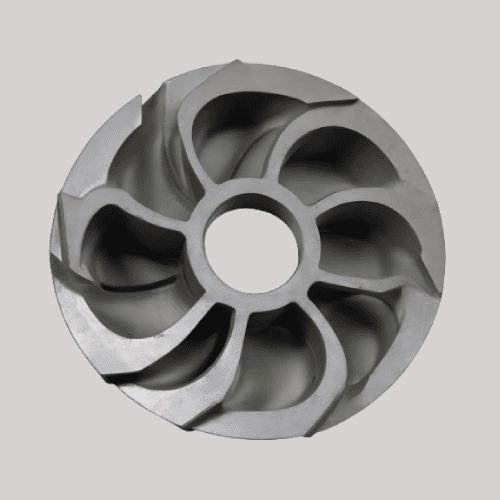

Pump Housing

Industrial Plumbing and Flanges

Industrial Machine Base

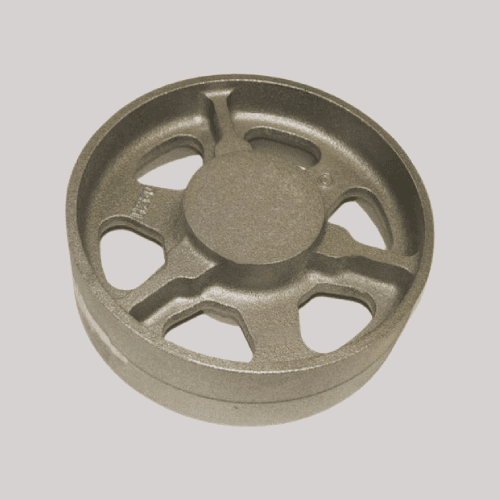

Equipment Belt Pulley

Electrical and Fittings and Connecters

Automotive Flywheel

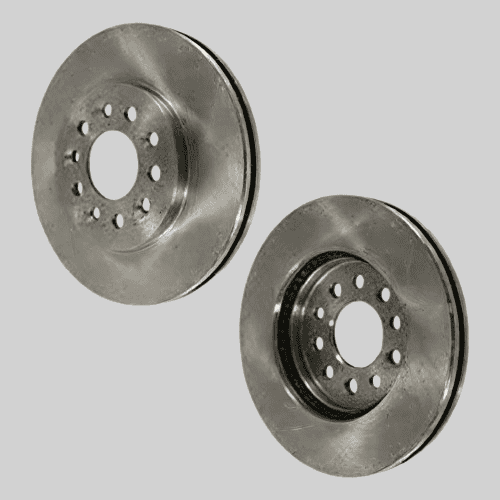

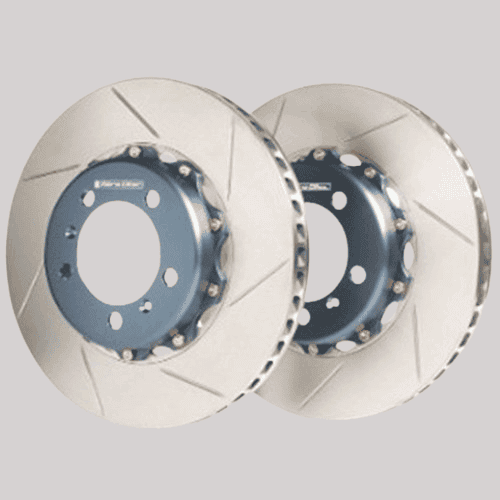

Iron Brake Rotor

Iron Pump Housing

Automotive Brake Disc

Products and Specifications

Applications

Special Solutions:

3- Stage Quality Control Process & Inspection:

- The quality assessment process with special testing equipment ensures only the finest products reach the buyers and customers.

- Here at Calmet, all the employees receive in-depth trainning, guidance, and potential elevation from the mentors or immediate managers who are always observant of the continuous progress and Lean philosophy (Kaizen).

- This intensive process ensures that the employees are well-equipped with the knowledge and work techniques as per their role in the organization.

- This task and its needed output will be perfect if performed with thorough understanding. It's crucial for our quality department to look in and stringently advise on any necessary changes to be made to ensure the scope of errors is minimized or removed.

Raw material

- Immersion Spectrometer with 24 Elements

- Sand Testing Facilities

- Universal Tensile Testing Machine

- Image Analyzer

- On-line Mould checking Facilities

Dimensional

- Coordinate Measuring Machine (CNC-CMM) – Range: 1m x 1m

- Linear Measuring Machine (LMM) – Range: 1m x 1m

- Profile Projector

- Digital Height Gauge – Range: 1m

- All kinds of Inspection Gauges & Instruments

Specialized

- Non-Destructive Test (X-ray)

- Ultrasonic Test

- Dye Penetrant Test

- Hydro Test

- Millipore Cleanliness Test

- Static Balancing

CASE STUDIES – EXPERTISE DEMONSTRATION

Case Study 1: Gray Iron Casting for Pump Applications

Client Background

A leading pump manufacturer required high-quality castings for their pump components. They needed sturdy and corrosion-resistant materials that could withstand the demanding conditions encountered in various industrial applications.

Solution

Calmet suggested utilizing gray iron for the pump components, considering its excellent castability, damping capacity, and cost-effectiveness. Working closely with the client’s engineering team, the firm manufactured custom gray iron castings that precisely met the pump’s specifications.

We employed sand casting techniques and implemented strict quality control measures to ensure the castings’ dimensional accuracy and structural integrity. They conducted thorough testing to verify the castings’ corrosion resistance and mechanical properties, ensuring they met the client’s stringent requirements.

Result

The gray iron castings delivered by us proved to be an ideal choice for the pump manufacturer. Thanks to their exceptional strength, corrosion resistance, and ability to dampen vibrations, the pump components achieved enhanced performance and reliability.

The client was highly satisfied with the firm’s ability to deliver top-quality gray iron castings that met their specific application needs. The successful collaboration led to a long-term partnership between the pump manufacturer and Calmet.

Case Study 2: Ductile Iron Casting for Automotive Suspension Parts

Client Background

A renowned automotive manufacturer required ductile iron castings for their latest suspension system components. The client needed materials capable of withstanding high loads, shock absorption, and maintaining dimensional stability under extreme conditions.

Solution

Calmet recommended ductile iron, known for its excellent tensile strength, impact resistance, and durability, as the optimal material for automotive suspension parts. Collaborating closely with the client’s design team, the firm designed and manufactured ductile iron castings that met their precise specifications.

Employing advanced casting techniques, including shell molding and precision machining processes, the firm ensured the castings’ dimensional accuracy and surface finish. Rigorous testing was conducted on the castings to confirm their mechanical properties, meeting the automotive industry’s stringent standards for safety and performance.

Result

The ductile iron castings provided by our firm surpassed the client’s expectations. The castings’ high tensile strength and impact resistance contributed to the superior performance and safety of the automotive suspension system.

The client recognized us as a trusted partner for their expertise in ductile iron casting. The successful integration of the castings into their suspension components led to improved vehicle performance and increased customer satisfaction.

Case Study 3: White Iron Castings for Mining Equipment

Client Background

A mining equipment manufacturer needed white iron castings for their wear-resistant components, such as crusher liners, grinding balls, and chute liners. The client sought materials capable of withstanding severe abrasion and impact, ensuring extended service life in harsh mining environments.

Solution

Calmet proposed using white iron due to its exceptional hardness, wear resistance, and impact toughness. Working closely with the client’s engineering team, they designed and manufactured custom white iron castings optimized for the mining equipment’s specific wear applications.

The firm employed the lost foam casting method to achieve complex geometries and intricate details required by the client’s wear-resistant components. Stringent quality control procedures were implemented throughout the manufacturing process to ensure the castings’ hardness, microstructure, and dimensional accuracy.

Result

The white iron castings supplied by Calmet proved to be highly effective in addressing the client’s wear challenges. The castings’ superior hardness and wear resistance significantly extended the service life of the mining equipment components, reducing downtime and maintenance costs.

The successful implementation of the white iron castings strengthened the partnership between the mining equipment manufacturer and Calmet. The client regarded the firm as a reliable supplier for their ongoing wear-resistant component requirements.

Case Study 4: Malleable Iron Castings for Railway Track Components

Client Background

A railway infrastructure company required malleable iron castings for their railway track components, such as rail clips, rail joints, and fastening systems. The client needed materials that offered high tensile strength, ductility, and anti-vibration properties to ensure reliable and safe railway operations.

Solution

Calmet recommended malleable iron as the ideal material due to its combination of strength and ductility. Collaborating with the client’s engineering team, they designed and manufactured malleable iron castings tailored to the railway track components’ requirements.

The firm utilized green sand casting techniques and implemented rigorous quality controls to ensure the castings’ dimensional accuracy and mechanical properties. Stringent testing, including tensile strength and impact resistance evaluations, was carried out to verify the castings’ performance under the demanding railway conditions.

Result

The malleable iron castings provided by us proved to be an excellent choice for the railway track components. The castings’ high tensile strength, ductility, and anti-vibration properties ensured reliable and safe railway operations, minimizing the risk of track failures.

The client acknowledged our expertise in malleable iron casting and established a long-term partnership for their railway infrastructure projects. The successful implementation of the castings contributed to the efficient and reliable functioning of the railway system.

Why Calmet?

To maintain a competitive advantage in the steel casting industry, Calmet always evaluates its unique strengths and value proposition. Here are some factors to consider while analyzing the competitive advantage that Calmet offers:

Quality and Expertise

- Expertise and experience in specialized casting processes, such as investment casting or sand casting, provide an edge over competitors.

- Certification of quality standards, adherence to industry-specific regulations, and continuous improvement initiatives have immensely helped Calmet and its customers.

Technological Capabilities

- Cutting-edge technology and equipment that Calmet employs significantly enhance the efficiency and quality of the manufacturing process.

- Investment in advanced machinery, automation, and digital tools can lead to cost savings, faster production cycles, and better casting outcomes.

- Strong R&D capabilities to develop new alloys and casting methods can differentiate a firm from its competitors and attract customers seeking innovative solutions.

Supply Chain Management

- Efficient supply chain management, including sourcing raw materials, logistics, and inventory control, can optimize costs and lead times.

- Building reliable relationships with suppliers and ensuring a steady supply of high-quality raw materials can give the firm an advantage in meeting customer demands promptly.

- Implementing just-in-time manufacturing practices and adopting lean principles can enhance competitiveness by minimizing waste and maximizing efficiency.

Customer Relationships

- Developing strong customer relationships and providing exceptional customer service is a way of life at Calmet. Every employee is dedicated to this philosophy.

- Understanding customer requirements, providing technical support, and offering customized solutions have helped us stand ahead of competitors.

- Regular communication and engagement with customers to gather feedback and address concerns helps in continuous improvement and maintaining a competitive edge.

Cost Efficiency

- To remain competitive, controlling costs throughout the manufacturing process is crucial at Calmet.

- Implementing cost-effective production strategies, optimizing resource utilization, and managing overhead expenses helps minimize costs.

- Continuous evaluation of cost drivers and exploring opportunities to enhance operational efficiency contribute to long-term profitability and competitive advantage.

Sustainable Manufacturing

Sustainable manufacturing focuses on minimizing the environmental impact and maximizing resource efficiency throughout the manufacturing process using the below commonly used techniques:

- Energy Efficiency: Implementing energy-efficient measures like optimizing furnace operations, adopting energy-saving technologies, and utilizing renewable energy sources.

- Waste Management: Implementing effective waste management techniques, including recycling and reusing materials, reducing waste generation, and implementing proper disposal methods.

- Resource Conservation: Employing techniques to reduce water consumption, optimize raw material usage, and minimize emissions.

- Supply Chain Transparency: Ensuring transparency and responsibility in the supply chain, such as sourcing materials from sustainable suppliers and monitoring the social and environmental impacts of the supply chain.

New Technologies

Innovative technologies can revolutionize the steel casting manufacturing industry, enhancing efficiency, quality, and customization capabilities. Some notable advancements at Calmet include:

- 3D Printing: The introduction of 3D printing in steel casting allows for complex shapes and design optimization, reducing material waste and lead times while enabling customization.

- Automation and Robotics:Integration of automation and robotics streamlines production processes, enhances precision, improves safety, and increases productivity.

- Data Analytics and AI: Leveraging data analytics and artificial intelligence can enhance quality control, predictive maintenance, and process optimization, resulting in improved efficiency, reduced costs, and enhanced product quality.

- Augmented Reality (AR): AR technology can assist in training, remote maintenance and repair, and real-time quality assurance, improving operational efficiency and reducing downtime.

Industry Regulations

The steel-casting manufacturing industry is subject to various regulations, which ensure safety, quality, and environmental compliance. Key regulations include:

- Workplace Safety: Regulations governing occupational health and safety, including maintaining safe working conditions, providing proper protective equipment, and adhering to workforce safety standards.

- Environmental Compliance: Regulations related to emissions control, waste management, pollution prevention, and resource conservation to mitigate the environmental impact of operations.

- Quality Standards: Compliance with quality certifications such as ISO 9001 ensures that products and processes meet internationally recognized quality standards, fostering customer trust.

- Supply Chain Traceability: Regulations and standards may require documentation and traceability of raw materials, ensuring responsible sourcing and avoiding materials with ethical or environmental concerns.