In response to the growing demand for durable and high-performance components in diverse industries, our steel casting development team embarked on a journey to enhance efficiency and durability through advanced technologies. This case study highlights a successful project that showcases our commitment to innovation and excellence in steel casting.

Objective:

Our primary objective was to develop a steel casting solution that not only meets stringent industry standards but also exceeds performance expectations. The focus was on im

Methodology:

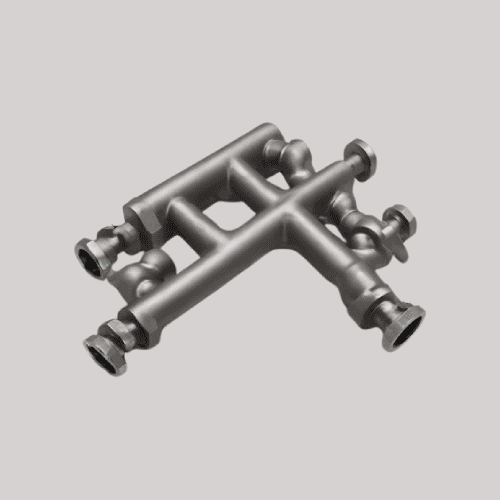

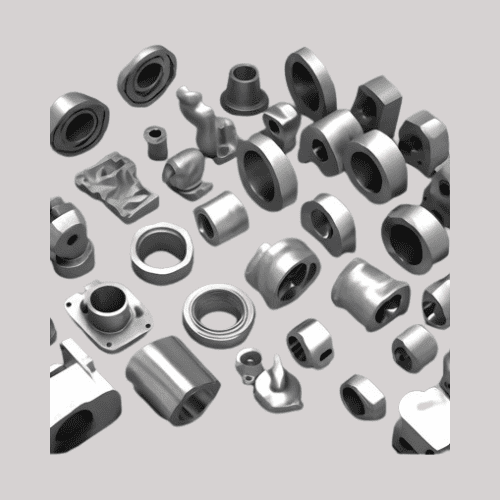

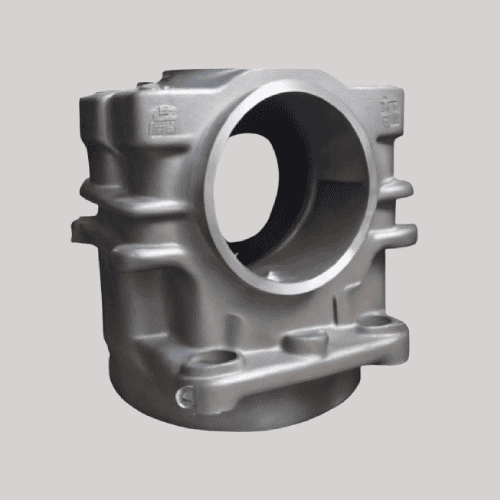

- Material Selection: Thorough research led to the identification of an advanced alloy with superior mechanical properties, including increased strength and wear resistance.

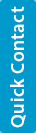

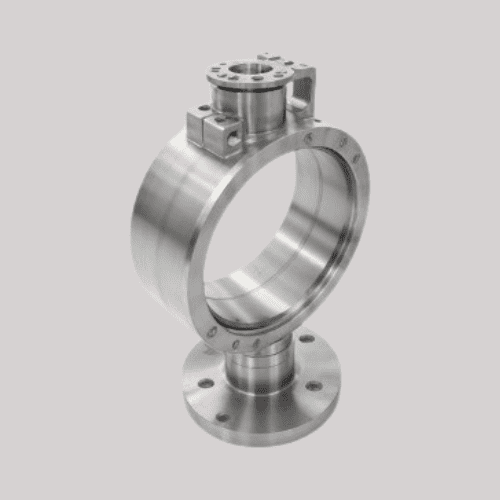

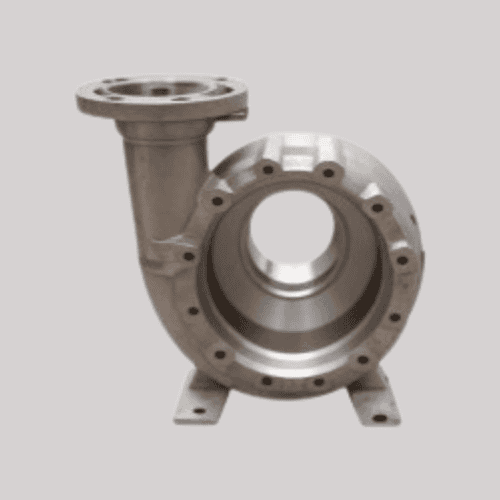

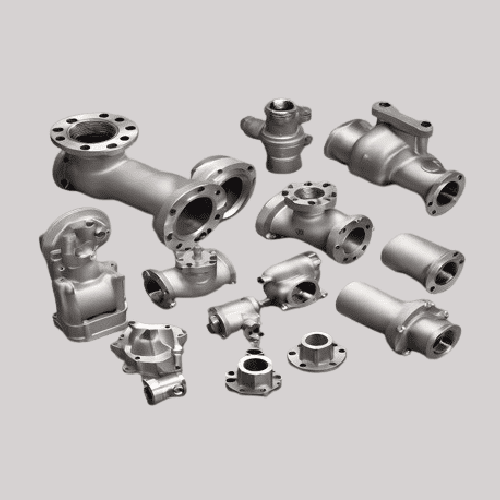

- Computer-Aided Design (CAD):Utilizing cutting-edge CAD technology, our engineers created intricate designs to optimize the casting process and enhance component performance.

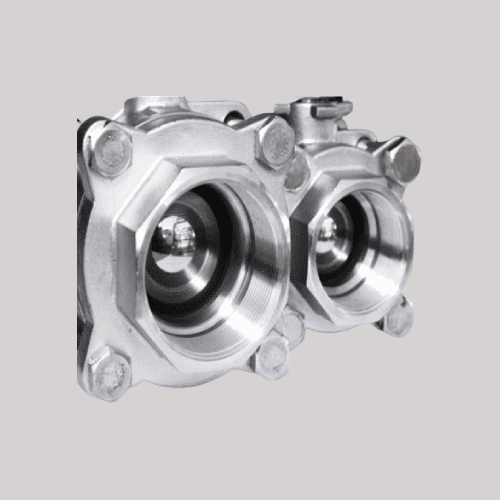

- Simulation and Prototyping: Advanced simulations were conducted to analyze the casting process, identify potential issues, and optimize parameters. Prototyping allowed us to validate the design and assess the feasibility of mass production.

- Innovative Casting Techniques: Implementing state-of-the-art casting techniques, such as vacuum-assisted casting and precision molding, contributed to reducing defects and enhancing the overall quality of the steel castings.

- Quality Control Measures: Rigorous quality control measures, including non-destructive testing and dimensional inspections, were integrated into the production process to ensure the highest standards of quality.

Results:

The developed steel casting solution demonstrated remarkable improvements in:

– Strength and Durability: The advanced alloy significantly increased the strength and wear resistance of the cast components, extending their operational lifespan.

– Production Efficiency: Implementation of innovative casting techniques reduced production time, enhancing overall efficiency and cost-effectiveness.

– Quality Assurance: Stringent quality control measures ensured that each casting met or exceeded industry standards, providing our clients with reliable and high-performance components.

Conclusion:

This case study exemplifies our dedication to pushing the boundaries of steel casting development. By embracing advanced materials, cutting-edge technologies, and meticulous quality control, we successfully delivered a solution that enhances efficiency and durability. Our commitment to innovation positions us as a reliable partner for industries seeking top-tier steel casting solutions.